Air blow-off systems use high-speed air currents to remove unwanted debris from a product line. This debris can be fluid or solid matter. Normally speaking the removal of solids is limited to fairly dry, not sticky residues and, similarly, liquids removal is normally not possible with air systems if it is very viscous and sticky. Nevertheless, air blow-off systems are an efficient and easy way to remove unwanted particles from a huge variety of manufacturing processes.

Compressed air Vs blower

There are two basic methods of achieving the necessary air currents for air blow off. Either a fan or blower device can be installed or a compressed air system can be used. The Air Nozzle Peoples products air all powered by compressed air. The various nozzle types used in these systems are designed to enhance and optimise the compressed air used.

Nozzle Types Used

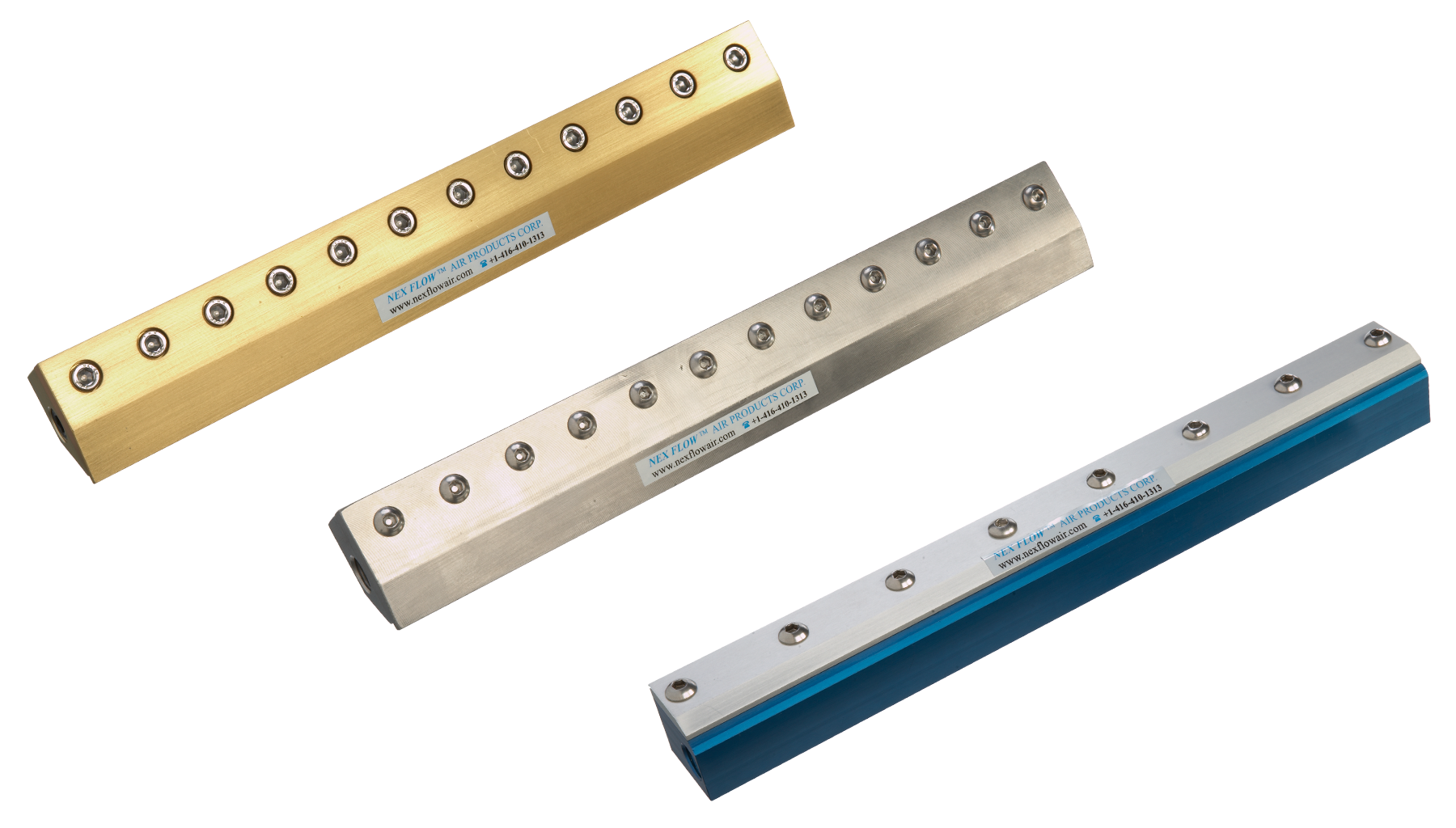

Four basic nozzle types are used in air blow-off systems. Simple air nozzles are used for spot blow of systems where a precise jet of air is required to target a specific point. To broaden the target area but with a corresponding reduction in impact an air jet system might be deployed instead of an air nozzle. If a large area or production line needs treating then air knives, which produce a line of high-velocity air, are used. Finally, for very high impact systems an air edger may be deployed.

More details on correct product selection can be found in the engineering considerations section of this page.