The process of blasting water from a target that needs to be dried is distinct from the process of evaporative drying. With a blow off drying action the force of the air, rather than its water absorption properties, are used to drive the water from the target. Of course, evaporation also takes place as a secondary drying process as well.

As the objective of the exercise is to drive water from the target success depends on the air force being applied. Rapidly moving, focused air currents will help blast water from the surface being targeted. In general, the higher the impact (velocity) of the air the more rapidly the object will be dried. This is particularly true if the target is odd shaped like a bottle. Due to the shape of the bottle, regardless of which side the drying air blast is coming from some of the surface will be shielded from the initial blast. Air will tend to move around the entire object but this will be at a greatly diminished velocity when compared to its initial contact point. So, if we can maximise the initial contact velocity we can preserve enough air impact to deliver effective water blow off to the shielded parts of the target surface.

The need for high impact air force means that air-edgers, air knives and air jets are the most commonly used products.

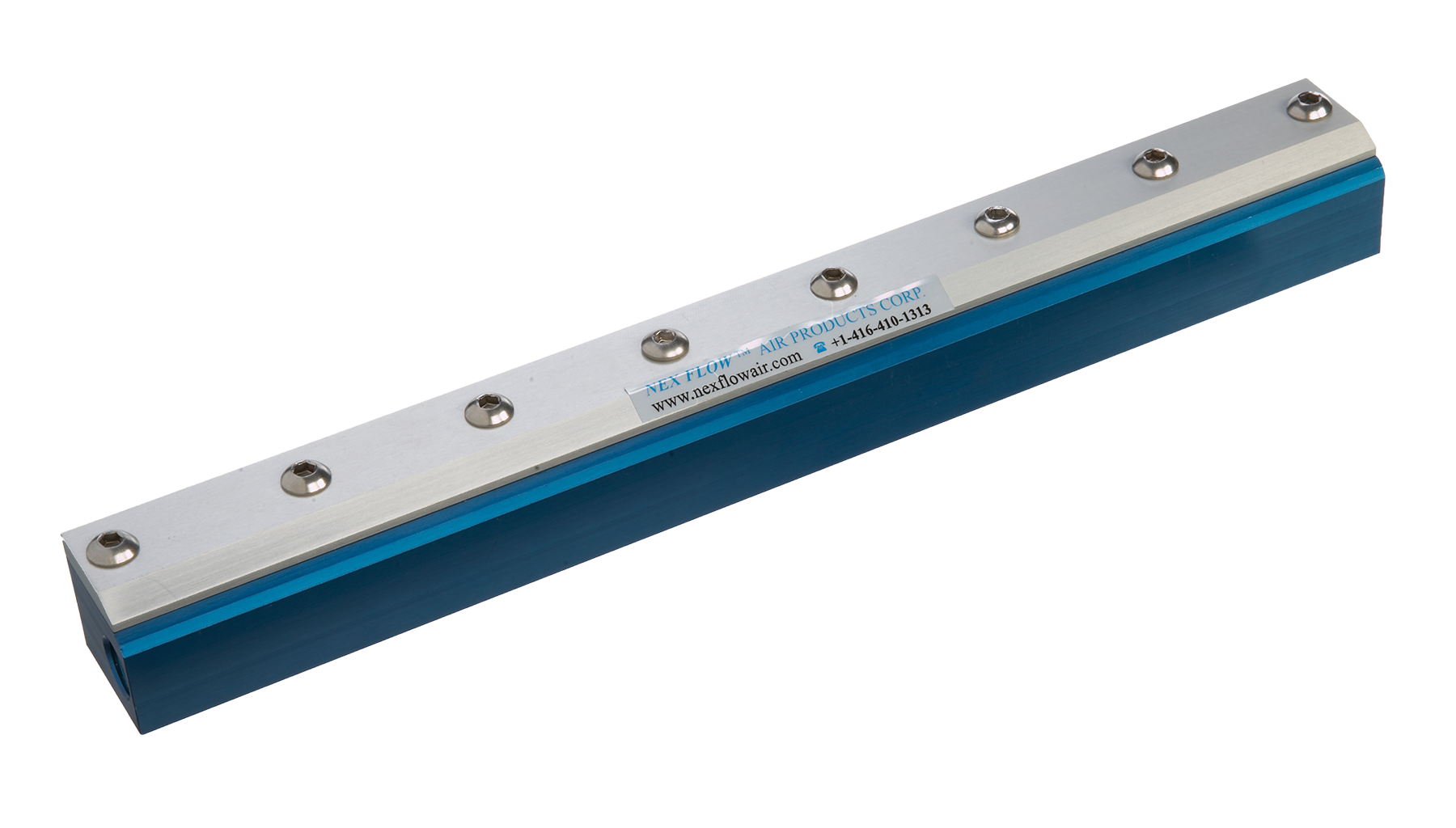

Air edgers are a good choice when maximum impact is required. For example, the product is very wet or moving rapidly on a conveyor OR when the object has a complex surface and so parts are shielded from the initial air contact.

Ring blades are and excellent choice for any object that can travel through the internal diameter. They deliver 360 degree high impact air flows and so will target the object being dried from all angles. The obvious limitation of the air blades is that they have a maximum size of about 11” diameter and so are not suitable for large objects.

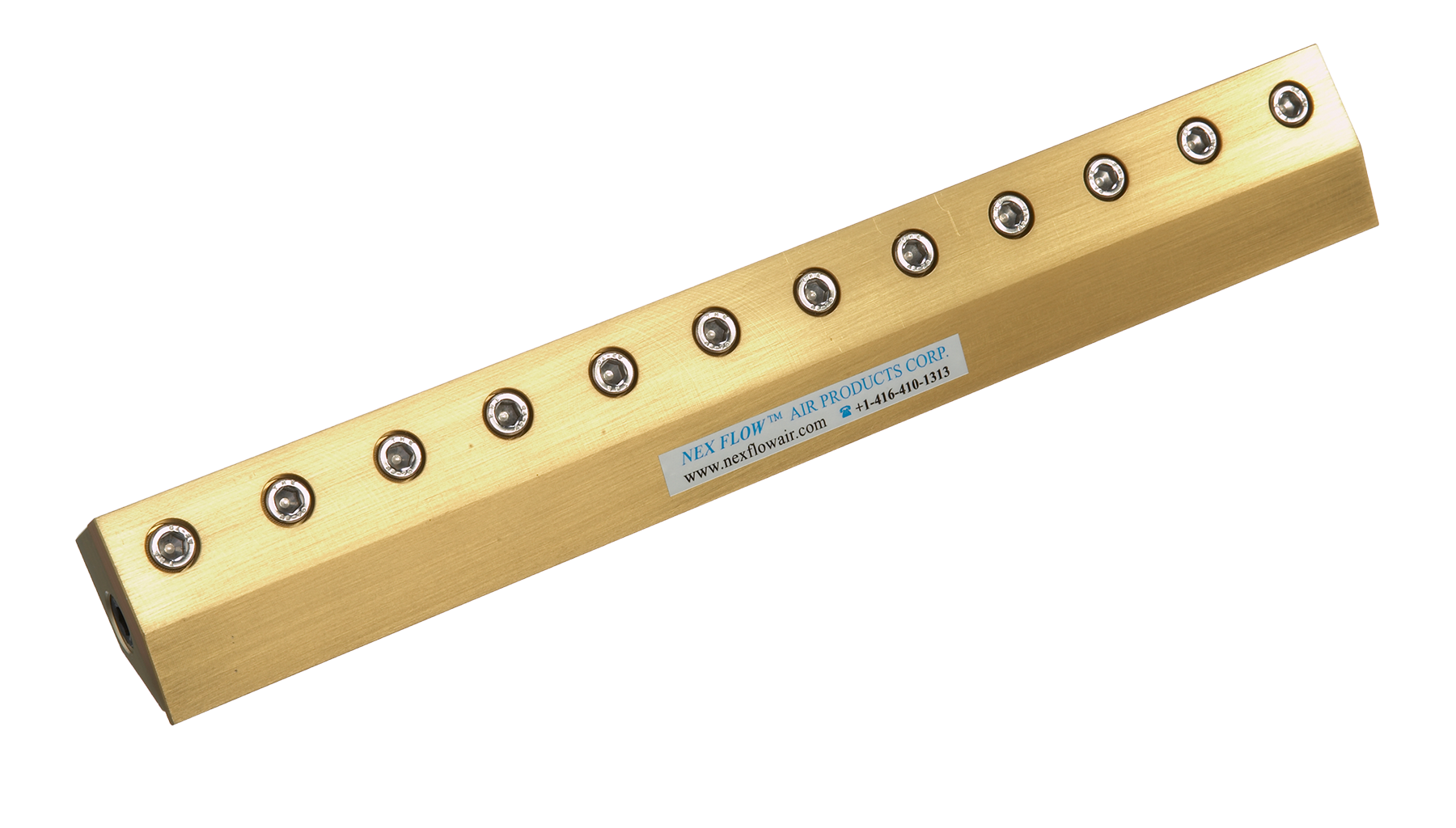

Air knives deliver high impact and very focused linear streams of air. Air knives can be made in lengths up to 54” (1371mm) and can also be daisy chained together to form even longer lengths. Air knives are a perfect water blow off solution for conveyor systems.