A vortex tube often seems like magic when first described but really it’s just a simple application of the laws of thermodynamics. Compressed air is injected into a shaped chamber as the air expands the chamber induces it to swirl very rapidly forming a vortex. The centrifugal forces in this this rapidly swirling air cause the lighter hot air and the more dense cooler air to separate in a similar manner to the way a centrifugal separator works.

Due to the way the vortex tube chamber is shaped the separated hot air stream from the vortex is moved in one direction and the cool air is moved in the other. The result is a hot air being exhausted and a much cooler air stream coming out the other end. The temperature differential can be very large with ambient temperature compressed air generating a hot air of 120 degree C and cool air of minus 50 degrees. This large differential is generated just from the motion of the air through the vortex generator. Essential what is happening is work is being done by the expanding air to produce a heat gradient – there is no magic just solid physics!

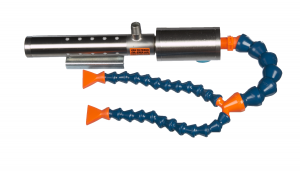

The devices listed here all operate with vortex tube technology and represent a variety of ways to bring this cooling power to various parts of the factory or industrial environment. One huge advantage of Vortex cooling is that it requires no power other than the air-line meaning it can often be deployed in situation where other forms of cooling cannot.