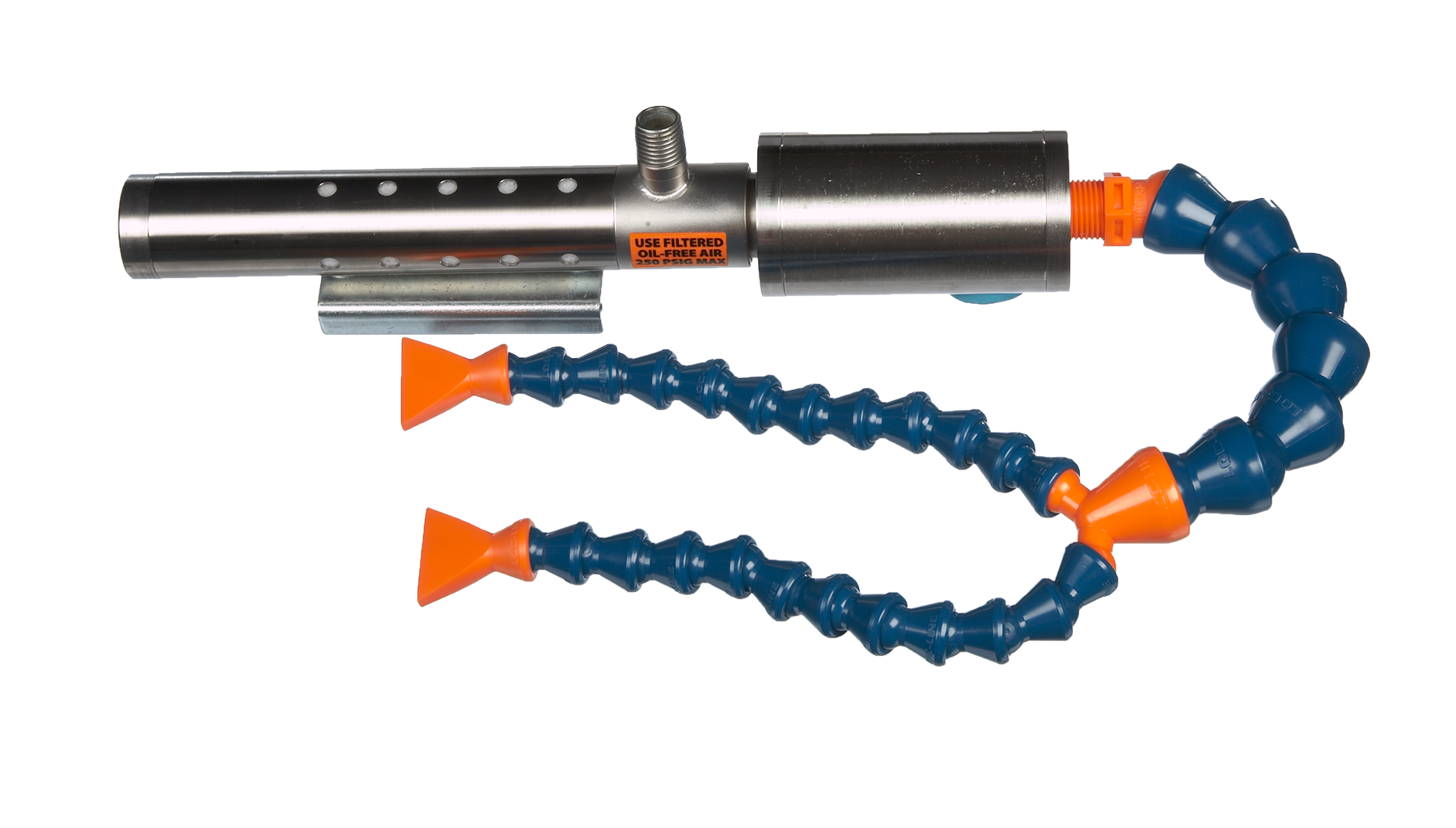

When a concentrated cooling effect such as in tool cooling then vortex tube technology is a good choice of product. The very cool air streams formed by the vortex tube can be directed to exactly where it is needed resulting in a concentrated blast of cooling at the potential hot spot.

If, however, the hot area does not need very cool air and simply needs a directed blast of ambient air to accelerate natural convective cooling then other, non-vortex tube, products should be considered. Standard air nozzles produce directed air streams suitable for spot cooling systems or, alternatively air jets will produce a slightly broader area of effect. The air streams from these products will not be much cooler than ambient but it will be moving fast and so will continually replace the warm air around the target and thus increase cooling rates.