The food processing industry has many uses for compressed air products in drying, air blow-off and cooling applications. Less commonly our products are also used to move powdered or granulated products around the factory in air conveying / hopper loading systems.

The food processing industry has many uses for compressed air products in drying, air blow-off and cooling applications. Less commonly our products are also used to move powdered or granulated products around the factory in air conveying / hopper loading systems.

Whatever the application the food industry has the following specific demands.

Hygienic materials

Hygiene and easy to clean parts are a must for all parts of the modern food production environment. We manufacture products in a number of materials suitable for use in a food environment. Specifically, 316 stainless steel options are found on most of our compressed air enhancement and vortex tube ranges.

In addition to the material/surface finish requirements of the consideration of the product needs to be given to the filtration of the air being used. Oil or other contaminants present in a compressed air line can have disastrous effects. As such we have a range of air filters and conditioners to ensure such contamination is eliminated.

Suitable for washdown environments

The need for strict hygiene means that food factories are washed down regularly. A general advantage of compressed air enhancement products over blowers and other alternatives is that they have no moving parts or power source other than the compressed air supply. This makes them intrinsically well suited for use in environments that are regularly exposed to wash fluids.

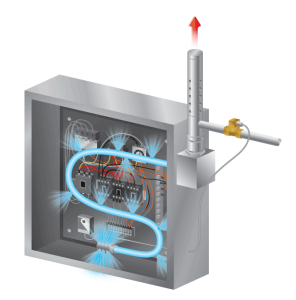

For products like cabinet coolers, which are often fitted to electrical enclosures, we provide these products with IP66 ratings. The cabinet cooler itself is not affected by water but, obviously, if fluid could make its way through the cooler then into the cabinet then it would be problematic. This means that the cabinet with the integrated cooler is able to be safely exposed to pressurised cleaning jets without fear of fluid making its way into the cabinet. The IP66 rating on such coolers means they can be exposed to powerful cleaning jets without fear of passing fluid through and into the cabinet

For products like cabinet coolers, which are often fitted to electrical enclosures, we provide these products with IP66 ratings. The cabinet cooler itself is not affected by water but, obviously, if fluid could make its way through the cooler then into the cabinet then it would be problematic. This means that the cabinet with the integrated cooler is able to be safely exposed to pressurised cleaning jets without fear of fluid making its way into the cabinet. The IP66 rating on such coolers means they can be exposed to powerful cleaning jets without fear of passing fluid through and into the cabinet

Example processes

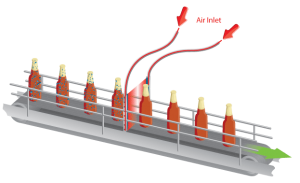

- Bottles and cans drying

- Vegetable drying after washing

- Conveyor cleaning (air blow off)

- Hopper loading (moving powdered products)

- Electrical cabinet cooling

- Cooling product after cooking / baking

Cooling for Food Processing

Spot cooling systems will deliver cool air to specific parts of a factory. For example, within electrical cabinets.

Specific examples include

- Bottle / can cooling (conveyor)

- Product cooling (conveyor)

- Electrical cabinet cooling (spot)

- Cooling baked product on trays (static cooling)

Drying for Food Processing

There are many parts of a food factory that need regular washing and so after wash fluid is applied they may also need drying. Air knives and air edgers are commonly used to enhance such drying applications in a food factory.

- Bottle and can drying

- Vegetable drying (after washing)

- Conveyor belt / tray drying

Product Moving for Food Processing

Compressed air conveyors can be used to move powdered or granulated food products around the factory. Most commonly these types of systems are used in hopper loading applications. The fact that no power source other than the compressed air line is required make air conveyors very easy to install and they are almost maintenance free.

Air Blow off for Food Processing

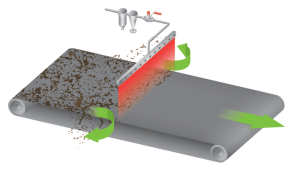

The use of air to remove debris from food processing lines is a very common use of our products. Air knives are used to deliver powerful lines of high impact air force over conveyor systems that will rapidly remove loose or waste product. For more directed air blow off precise air nozzles can be used to deliver jets of very high impact air to a targeted spot.

Alternatively, air knives can be deployed to form air barriers that will prevent product from exiting conveyor or hopper loading areas.

In addition to continual air blow off systems deployed in production lines we also have many manual air blow off guns for the spot cleaning of machinery.

Like our other products compressed air enhancement units like air knives only need a suitable air supply to work. They have no moving parts so are incredibly reliable and are able to be washed down without any fears about water ruining electric motors or other mechanical parts, because there aren’t any!

The use of air to remove debris from food processing lines is a very common use of our products. Air knives are used to deliver powerful lines of high impact air force over conveyor systems that will rapidly remove loose or waste product. For more directed air blow off precise air nozzles can be used to deliver jets of very high impact air to a targeted spot.

The use of air to remove debris from food processing lines is a very common use of our products. Air knives are used to deliver powerful lines of high impact air force over conveyor systems that will rapidly remove loose or waste product. For more directed air blow off precise air nozzles can be used to deliver jets of very high impact air to a targeted spot.