Airflow cooling

These products serve to enhance the action of compressed air by entraining the surrounding air via the Coanda effect. Essentially this increases the airflow over the target and so helps with convective cooling. The basic physics is that the warm air that has been heated by the target is rapidly and continually replaced by ambient air. This flux of air then speeds up the cooling process greatly.

It should be noted that although a compressed air expanding into an atmosphere will cool this gas this not the primary mechanism of these products. As large volumes of ambient air are entrained within the compressed air flow through the device the resulting overall air flow is not actually cooled to a great degree. So, whilst the resulting airflow might be a slightly cooler than ambient air, this heat differential is not hugely significant, it is the air flow and the resulting improvement of convective cooling that is the primary function of these products.

These types of product include air amplifiers, air nozzles and air knives. All these products work on the same basic principles but have vastly different air flow patterns and impacts. Selecting the correct air flow product for a given application is discussed in detail within this section of the ANP website under the engineering considerations.

Vortex Tube Cooling

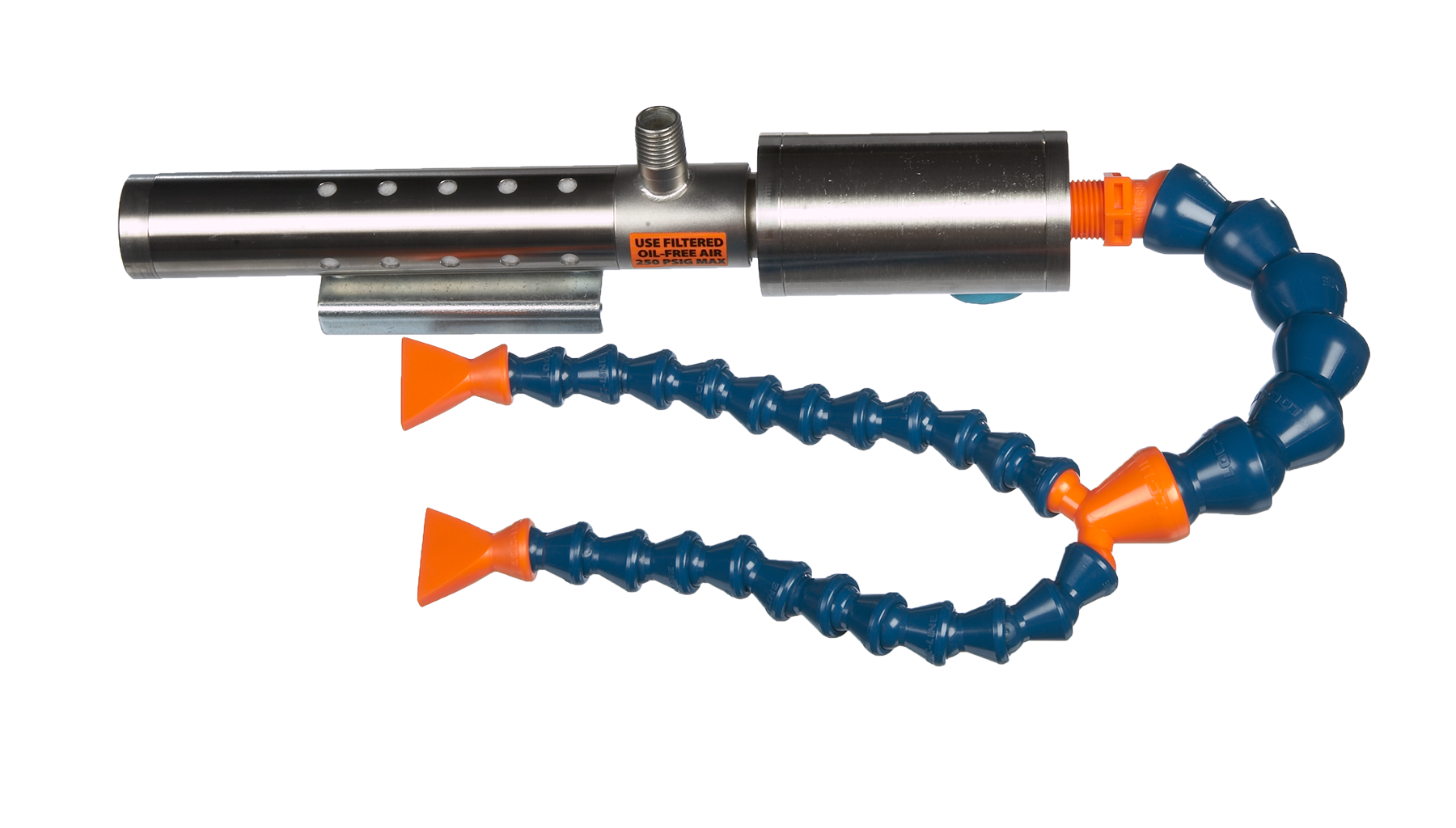

Unlike the air flow cooling products mentioned above the products based on vortex tube technology actually do cool the air significantly. The vortex tube is a fascinating device that utilizes basic thermodynamic principles to produce significant cooling in air streams. Compressed air enters the tube and is, as it expands, is forced into a rapidly rotating swirling flow within the tube. The very rapidly rotating air then acts as a centrifuge system which separates lighter (less dense) parts of the air from more dense parts. As hot air is lighter than cooler air what this means is that a heat differential is set up and cool air is forced one way through the tube and hot air the other way.

The resulting cooling is quite dramatic with ambient compressed air entering the tube and the split air having a temperature difference of over 130 degree C in some cases. At the cool end of the vortex tube air flows as cool as minus 50 degree C can be achieved. This cold air can then be applied to cool whatever is required.

Products based on vortex tube technology include cabinet coolers, adjustable spot coolers, mini cooler and mist aided spot coolers. The correct selection of each product is discussed in the engineering considerations sections of this page.