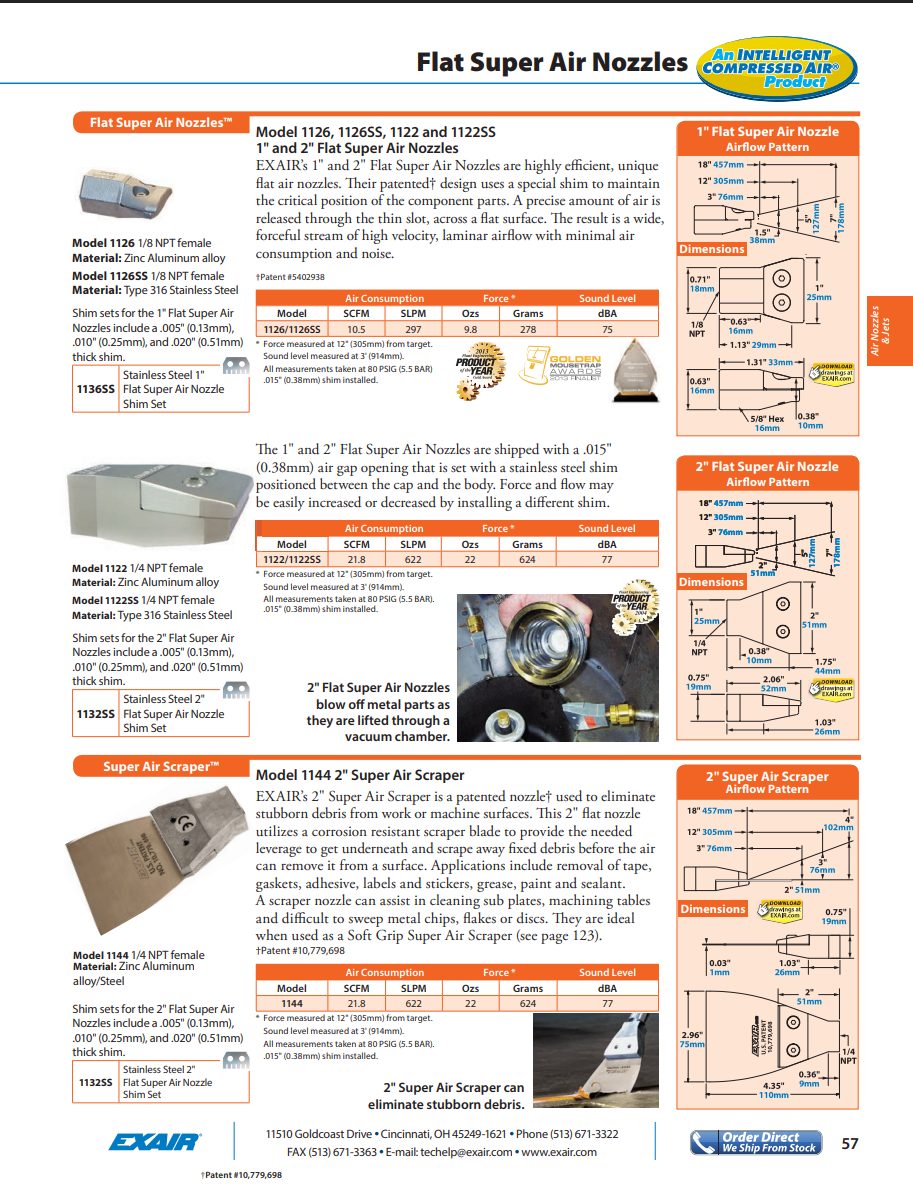

EXAIR Flat Super Air Nozzles™ air edgers are shaped to produce a greatly accelerated, high impact air flow. The shape of the nozzle housing serves to amplify the Coanda effect and so a large volume of the surrounding air is also entrained which greatly enhances the force of the air flow.

The result is a wide, forceful stream of high velocity, laminar airflow with minimal air consumption and noise. Force and flow may be easily increased or decreased by installing a different shim. It is available in zinc/aluminum alloy or 316 stainless steel.

Applications

- Part cleaning

- Chip removal

- Liquid blowoff

- Part cooling

- Material conveying

- Part ejection

- Fibre conveying

- Air assist

Advantages

- Reduced compressed air cost

- 10 dBA average noise reduction

- Conserve compressed air

- Improved blowoff performance

- Compact

- Improved safety

- Meets OSHA noise level requirements

- Meets OSHA pressure requirements

- Improved production

Materials

Zinc Aluminum alloy – general purpose applications. Max temp 250°F (121°C).

Type 316 Stainless Steel – high temperatures, corrosive environments, and mechanical wear. Max temp 1000°F (538°C)

Accessories

Shim Sets

Shim Sets

Stay Set Hose – For applications where frequent repositioning of standard force Air Nozzles or Jet is required, the Flexible Stay Set Hoses™ are ideal. Simply mount the hose in close proximity to the application and bend it to aim the airstream at the target. Since the hose has “memory”, it will not creep or bend. It always keeps the aim until physically moved to the next position.

Stay Set Hose – For applications where frequent repositioning of standard force Air Nozzles or Jet is required, the Flexible Stay Set Hoses™ are ideal. Simply mount the hose in close proximity to the application and bend it to aim the airstream at the target. Since the hose has “memory”, it will not creep or bend. It always keeps the aim until physically moved to the next position.

Swivel Fittings – make it easy to adjust the aim of the Air Nozzles and Jets. Correct placement of the blowing angle can help optimize performance, reduce noise levels and improve efficiency. Swivel Fittings permit a movement of 25 degrees from the center axis for a total movement of 50 degrees. Type 303 or 316 Stainless Steel.

Swivel Fittings – make it easy to adjust the aim of the Air Nozzles and Jets. Correct placement of the blowing angle can help optimize performance, reduce noise levels and improve efficiency. Swivel Fittings permit a movement of 25 degrees from the center axis for a total movement of 50 degrees. Type 303 or 316 Stainless Steel.

Magnetic Bases – are suited to applications where frequent movement of the Air Nozzle or Jet is required. The powerful magnet permits horizontal or vertical mounting that will hold the blowing position of the Stay Set Hose. A shutoff valve is provided that can be used to vary the force and flow.

Magnetic Bases – are suited to applications where frequent movement of the Air Nozzle or Jet is required. The powerful magnet permits horizontal or vertical mounting that will hold the blowing position of the Stay Set Hose. A shutoff valve is provided that can be used to vary the force and flow.